Gratings (GRP)

Glass fiber reinforced plastic (GRP) walkway gratings are made of fiberglass and resin combined in a dedicated mould. This creates a plastic grating with specific chemical and mechanical properties dependent on the selected type of resin. The ratio of fiberglass to resin is 35% to 65%.

The advantages of GRP

- Corrosion-resistant;

- Fire-retardant;

- Durable;

- Anti-slip;

- Lightweight;

- Maintenance-free;

- Not electrically conductive.

Types of resin

As standard, Fiberstruct GRP gratings are available in four types of resin:

|

Orthophthalic |

|

resin is resistant to atmospheric corrosion. |

|

Isophthalic |

resin is extremely suitable for a corrosive and chemical environment and is highly fire-resistant with controlled spreading of smoke. |

|

|

Vinylester |

is extremely resistant to chemicals, such as acids, salts, and other corrosive substances. This type of resin is also highly fire-resistant. |

|

|

Phenol |

resin is optimally resistant to chemicals and is extremely fire- resistant and gives off very little smoke. This type of resin is often used in offshore applications. |

Overview of types of resin

|

Abbreviation Type of resin |

Basic Resin |

Description |

Standaard Colours |

Fire Resistance |

|

ORTHO |

Orthophthalic polyester |

Resin is resistant to atmospheric corrosion.

|

Grey (RAL7040) |

Fire-resistant |

|

ISO |

Isophthalic polyester |

Resin is extremely suitable for a corrosive and chemical environment and is highly fire-resistant with controlled spreading of smoke.

|

Green (RAL6010) Grey (RAL7035) |

Highly fire-resistant |

|

VE |

Vinylester |

Is extremely resistant to chemicals, such as acids, salts, and other corrosive substances. This type of resin is also highly fire-resistant.

|

Orange/Red (RAL2002) |

Extremely fire-resistant |

|

PH |

Phenol |

Resin is optimally resistant to chemicals and is extremely fire- resistant and gives off very little smoke. This type of resin is often used in offshore applications.

|

Black (RAL9004) |

Best fire resistance with minimum formation of smoke |

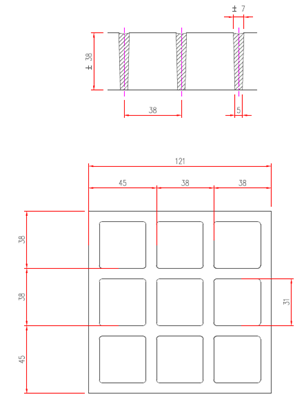

Mesh width

Fiberstruct GRP gratings are available in the following thicknesses and mesh widths:

|

Grating thickness (in mm) |

Grating mesh width (in mm) centre-to-centre |

Grating mesh width inside (in mm) |

|

13 |

51 x 51 | 45 x 45 |

| 25/30/38 | 38 x 38 | 32 x 32 |

| 30/38 Micromesh | 19 x 19 | 13 x 13 |

| 51 | 51 x 51 | 43 x 43 |

Standard sizes

As a manufacturer of plastic gratings, Fiberstruct has a variety of standard sizes in stock. Click here for an overview of the standard sizes.

Custom solutions

If desired, we can cut every imaginable shape or size. Our specially equipped high-tech cutting department provides quality custom solutions. As a rule, we use the drawings provided by our customers, but we can also have our own engineers draw up a comprehensive grating plan.

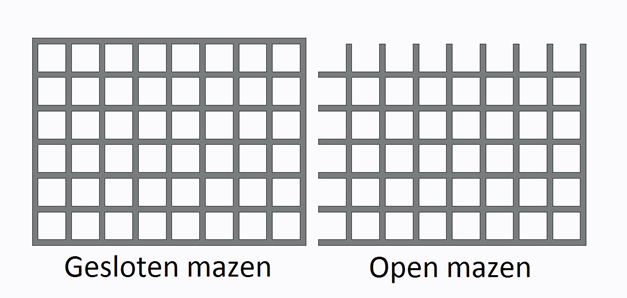

Closed sizes

Custom-cut GRP gratings can be provided with open and closed meshes. Click here for an overview of the sizes with closed meshes that we can provide to you from our stock.

Top layer

Fiberstruct plastic walkway gratings are available with different types of surfaces.

|

Grit surface |

|

In some circumstances, it may be desirable to have your GRP gratings provided with a grit top layer. This top layer is available in a variety of grain sizes. The grit top layer does not necessarily make the grating more anti-slip, but does offer some additional advantages. For example, it is more aesthetic to the eye and provides a comfortable feeling underfoot. |

|

Concrete surface |

As standard, Fiberstruct plastic gratings are anti-slip because of the concave (meniscus) surface. This surface satisfies standard R13 of BGR 181 and DIN 51130. As an end user, you are assured of optimal and continuous safety. |

|

|

Sealed surface |

As an alternative to open grating, we also provide sealed (HLU) panels. HLU panels are sealed on top. As standard, the surface is fitted with a grit top layer to provide the anti-slip effect. This increases the thickness of the grating by about 3 to 5 mm. These panels are also available as a sandwich panel where both the upper and lower sides have a closed surface. |

|

|

Smooth surface |

In some sectors, such as the food industry, there is a high risk of bacterial infection. In these industries, cleanliness and hygiene are extremely important. For such an environment, Fiberstruct has plastic gratings with a calibrated smooth surface. |

Basic colours

The basic colours of our Glass fiber Reinforced Plastic gratings are:

- Grey (RAL 7035);

- Green (RAL 6010);

- Orange-Red (RAL 2002).

We keep these gratings in stock in a variety of sizes (available on request). All other RAL colours can be provide upon request.

Clips

To fasten the plastic gratings and stair steps in place, we have a wide assortment of clips and materials. These are available in high-quality stainless steel (A2 and A4) and thermally galvanised versions.